Macerating Process Pump

The Gorator® sizes, reduces, disperses, separates, delumps, grinds, chops, macerates and it even pumps.

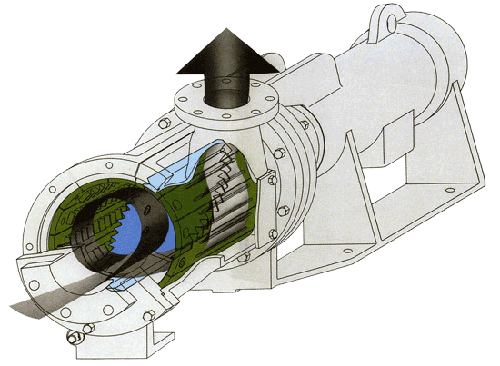

The Gorator® works on a simple inclined rotor principle, which gives the machine it's self-cleaning, non-clog, trouble-free characteristics under the most difficult conditions. An impeller, taking the form of a flat plate is mounted at an oblique angle on the end of the pump shaft. Rotation of the impeller produces a centrifugal action which pumps the material and discharges it radially through the outlet. Notched teeth in the rotor plate mesh with teeth in peripheral stator bars to chop the material during its passage through the pump.

Mixing and dispersion intensity can be readily controlled by the user and the Gorator® can run dry or partially dry without risk of damage so long as the seal area is flushed.

The Gorator® can be adapted to meet a wide variety of needs in an ever-increasing number of industries. It is easily fitted to meet individual reducing needs by spacing the liner bars to exactly the position required for various size particulates. Synthetic fibres, sludges, slurries, high-density pulp, rubber dispersions, slaughter house residue, high-viscosity materials, chemical residue, industrial waste and paper stocks are but a few of the materials being successfully handled by the Gorator®.

Gorator® Features

- 3 machines in one

- High Shear Performance

- Unobstructed Inlet

- Infinitely Variable Discharge Slots

- No Metal to Metal Contact

- Quick Opening Casing

- Heavy Duty Construction

- Handles Products with Viscosities to 100,000 cps

- Lower Hp, RPMs

Gorator® Benefits

- Saves on Equipment Costs

- More intense dispersion than with Conventional machines

- No Clogging, Easy Feeding and Discharge

- Unlimited Process Flexibility

- Reduces Wear

- Easier Inspection, Cleaning of Tramp Material

- Longer Equipment Life

- Protects Auxiliary Pumps

- Saves Energy, Reduces Wear

The Gorator® is available in three basic models:

- The 6X4X10 for maximum flow and controlled size reduction, complete mixing, stripping, dispersion or delumping in industrial applications.

- The 4X3X8, which was designed especially for the tough sludge, scum or screenings service in sewage treatment plants or lower flow rates in industrial applications.

- The 4X4PP for mixing and dispersion of liquid/liquid and liquid/solid material, and pumping out grit laden fluids.

Typical Applications:

Pulp & Paper

This rugged processing machine solves many problems in pulp and paper mills. The Gorator® prevents plugging of black liquor guns in recovery boiler systems. It breaks up ground wood bull-screen rejects. It has proven very effective in dispersing wet-strength secondary fiber. And because the Gorator® is so efficient in breaking, deflaking and fiberizing, it gives mills 50% more production out of pulpers reducing total required horse-power days per ton. It's also economical for small peripheral repulping systems.

The meshing of rotor plate and stator teeth makes for a very efficient shearing action, but a running clearance for 1/16th" allows the Gorator® to fiberize, deflake, and shred without cutting fibers.

In one application in the pulp and paper industry, the Gorator® is being used in pulp mill effluent dewatering to disintegrate sedimentation tank underflow sludge prior to dewatering by centrifuge. In pulp mill effluent skimming, it disintegrates floating chips, bark and other debris prior to their combining with underflow sludge. And in another application, mechanical pulp manufacturing, the Gorator® disintegrates bull-screen rejects prior to pumping to the waste lagoon.

Industrial Wastewater

A variety of industries find the Gorator® useful in processing industrial wastewater.

It is being used by chemical and petrochemical plants to disintegrate liquid waste prior to incineration. Waste is recycled around hot and cold tar holding tanks to protect feed pumps and incinerator nozzles.

The Chemical Process Industries

The Gorator® sizes, shreds and pumps plastics, rubber and adhesives. FLSmidth Minerals' mighty Gorator® is several machines in one. It saves time, space and money for a quicker payback on the initial investment for companies in the CPI who are using it in many ways. The Gorator® controls particle size to prevent clogging of lines in polymerization and crystallization trains, providing hazard free screening and uninterrupted production. It disperses polymers and rubber in a solvent. It separates such materials as agglomerated polymer pellets. It is used in the extraction process from plant stocks in pharmaceutical manufacture. It disintegrates wastes to prevent nozzles and valves from clogging. And it handles a host of other size reduction, shredding, extraction, separation and disintegration chores.

Food Processing

The Gorator® eats up the challenges of size reduction and dispersion. It can be used for a variety of heavy-duty macerating jobs in food processing plants - disintegrating, shredding and controlled sized reduction. It is being used successfully in such applications as fish wastes, citrus peels, secondary vegetable products (for reducing the volume prior to disposal), tomato processing and for grinding bones, fat and gristle for rendering. Moreover, the Gorator® has been built to stand up to, and survive, the heavy stresses induced by the shearing action. The Gorator® is also used for wastewater processing in the food industries to grind spent hops in brewing.

The 438 Gorator® For Municipal Applications:

The 4x3x8 is designed and built for survival under tough sludge screening and scum and sludge disintegration service. Size reduction and disintegration is a back-breaking test for any sludge grinder. But the 4x3x8 Gorator® has been specifically designed to stand up to and handle this rough service. It is the most cost effective unit of its type on the market, offering saving in wear, maintenance and power use. To make it more durable, especially with the presence of a grit residue, the new Gorator® uses tool steel for the liner bars. And to reduce wear and power consumption, it operates at a low speed - 900rpm. Current municipal wastewater treatment applications of the Gorator® include sludge, scum, screenings and liquid waste disintegration.

Gorator® Units For Process Applications:

GN (horizontal) 6x4x10

Construction: Split casing, inlet flange and adapter plate furnished in cast 304 stainless steel. Rotor plate, liner bars, end liner segments are precision cast and polished 17-4 PH, abrasion resistant stainless steel.

Seal Assembly: Either lantern ring and packaging or double mechanical seal.

Rotor: 10" dia., notched.

Liner Bars: Grooved, discharge slots can be adjusted in 3/16" increments for highly variable process requirements. Processes whatever enters through 6" inlet. Discharge outlet is 4". Horsepower varies up to 100HP at 1800rpm.

GNV (vertical) 6x4x10

Construction: Seal assembly, rotor and liner bar specifications are similar to 6x4 GN. This machine is built in a vertical configuration to macerate chunky materials that do not flow easily. It may be connected directly to the bottom of a mixing vessel to accelerate mixing, dispersion and extraction due to the vortex action of the impeller. Available with packing construction as standard.

438 (horizontal) 4x3x8

Construction: Cast iron. Rotor plate is hardened steel. Liner bars are investment cast 17-4 PH (S.S.) or CD2 tool steel, and end rings are WS Meehanite.

Seal Assembly: Double mechanical seal is standard.

Rotor: 8" dia. impeller.

Liner Bars: Discharge openings can be varied with combinations of standard parts. Inlet is 4", discharge outlet is 3". Features large diameter, short over-hang shaft for minimal deflection under shock loads. Horsepower ranges up to 60@ 1800rpm. 870 rpm v-belt drive is standard for abrasive wastewater applications.

Gorator® For Pumping Only & Gorator® Performance Curves

PP (V angled pump) 4x4

About: The Gorator® Type PP is a clog-free sludge/slurry/grit pump that easily handles difficult materials. Heavy slurries, sludges, pulps, oversize wastes and high viscosity materials all flow easily through the Gorator®. A unique V-shaped rotor and clean internal design ensure free passage of all solids... no binding or clogging.

Operation is Simple: The V-shaped rotor is mounted on the end of the pump shaft, resulting in an unrestricted inlet and its unique flat rotor surface effects a positive displacement action on extremely heavy slurries and a purely centrifugal action on lighter liquid streams. The flow pattern is direct with no chance for solids build-up or clogging. The pump can be run dry or partially dry without damage as long as the seal area is flushed. Pump case is wear-resistant heat-treated Meeharite and the rotor is formed steel. Rotor and shaft are dynamically balanced. Stuffing box has standard graphite impregnated Teflon® packing. Ball bearings are oil lubricated, double row, and are sized to safely carry all radial and thrust loads. Inlet and outlet ports are 4-inch flat faced 125# flanges. There is an inspection port in the tangential discharge of the pump for easy access to the interior of the pump case.

Construction: Wetted parts wear and impact resistant, heat-treated WS Meehanite. Rotor assembly abrasion resistant steel. Shaft heat treated 4140 steel. Bearing frame of cast iron.

Seal Assembly: Water lubricated conventional packed stuffing box.

Rotor: Dynamically balanced 8", V-angled. This non-clog pump is especially suited for high viscosity slurries containing large quantities of debris. Has large clean-out port in volute housing. Usually furnished with vari-drive motor for flow rate control and minimum horsepower usage and wear. Horsepower ranges up to 60@ 1550 rpm.

Represented in Canada by:

ICR Water Technologies Inc.

3-200 Memorial Avenue, Suite 101

Orillia, Ontario

L3V 5X6

Phone or Fax to: (888) 281-7774

For more information on this product and to view the in-depth statistics please click here to read the full PDF brochure.