Pulse Transfer Thickening: A Cost Effective Solution to Sludge Dilution Problems in Wastewater Treatment Plants

"Pulse Transfer Thickening (PTT) is a term developed by FLSmidth Dorr-Oliver. PTT describes the capability of the ODS® pump to eliminate dilution when sludge is withdrawn from a clarifier."

The ability to match the pumping rate to the settling rate is what "Pulse Transfer Thickening" is all about. To achieve this, the ODS® pump transfers at LOW flow rates to enhance the ability of the solids to settle in the clarifier. This maximizes your clarifier efficiency.

The ODS® pump operates by displacing its pumping cavity in less than two seconds which generates scouring velocities equal to electrically driven pumps moving in excess of 200 gallons per minute through the piping. The pulsing action of the ODS® pump prevents piping from plugging.

Not only does this process offer continuous percent solids feed to anaerobic digesters without coning, it does it automatically without any plant operations involvement short of turning the pump(s) on or off!

That's right! No air adjustments or cycle rate adjustments necessary.

The ODS® pump automatic controls offer the following:

- Automatic Air Adjustment: matching the required air pressure settings to the current head losses throughout the range of 2 to 100 psi air feed.

- Automatic Stroke Adjustment: matching the pump cycle rate to the clarifier settling rate maintaining a consistent biosolids blanket depth in your clarifier at all times.

- Automatic Moisture/Stroke Monitoring: the pump will shut down whenever a diaphragm fails or the pump cannot cycle due to a closed valve.

- Automatic Pump Sequencing: only one pump will cycle at any given time. This is useful for multiple pump installations with common discharge piping.

- Remote Operation: The ODS® Pump can be remotely operated by an existing PLC and computer interface. The controls can include an internal modem which will allow for remote, as well as off-site, monitoring for remote failure notification and program downloads should a pump fail.

What are the Benefits to Pulse Transfer Thickening?

- Typically 60% increase in primary sludge consistency.

- Typically 3 times greater consistencies in activated sludge wasted from a quiescent hopper

- Uniformly high consistency sludge

- Uniformly stable clarifier sludge blanket

- Clogging eliminated because of the ODS® pumps consistent turbulent velocity.

- Less over-all sludge volume due to higher % solids feed offering:

- Less digester capacity needed

- Less heat needed (lower energy costs)

- Less sludge volume to store

- Lower pumping costs

- Lower maintenance costs

- More detention time

- Higher methane yield

- More continuous (less batch) processing

- Increased system stability

- Less risk of thermal shock to bacteria

Introduction

Sludge blanket dilution is a universal problem in wastewater treatment plants. The problem occurs when too much sludge is pumped from the clarifier tank. Dilution mitigates the very reason for installing a clarifier in the first place by watering down sludge consistently. Then, when the plant has to move large volumes of diluted sludge, overall plant efficiency suffers and operating costs soar. Dewatering costs increase. Digester operations suffer and are more costly. Hosts of other problems arise, depending on the flow sheet. The fact is, dilution is very expensive. In most cases dilution is not the fault of the sedimentation unit. It is the fault of the method of pumping. But supposing there was a way to pump sludge from a clarifier without causing dilution; a way to assure that the plant could withdraw sludge of uniformly high consistency and avoid the problems that result from dilution? As incredible as it may seem, a pump costing only several thousand dollars can produce benefits in a wastewater treatment plant worth as much as $4,900/mgd a year in savings. What makes consistent withdrawal of uniformly thicker sludge possible is a concept FLSmidth calls Pulse Transfer Thickening. This introduction has been published to help consulting engineers who design wastewater treatment plants become more familiar with the benefits Pulse Transfer Thickening can yield, and better understand how those benefits are achieved. Pulse Transfer Thickening has been proven over the past two decades in wastewater treatment plants throughout the US. Considering the energy situation that persists these days, Pulse Transfer Thickening has considerable potential for helping plants operate more cost-effectively.

The Problem of Dilution Explained

Standard practice in designing pumping systems for withdrawing primary sludge has been influenced by these parameters:

- With a waste stream containing 200PPM of suspended solids, typically an accumulation rate of 2400 gallons per day of 5% primary sludge is sought for each MGD of influent, or 1.67 gallons per minute on a continuous basis.

- Piping of 6 to 8 inches in diameter, and even larger, is generally mandated.

- It is common practice to design for a minimum velocity of 2.5 feet per second withdrawal rate to prevent clogging the lines.

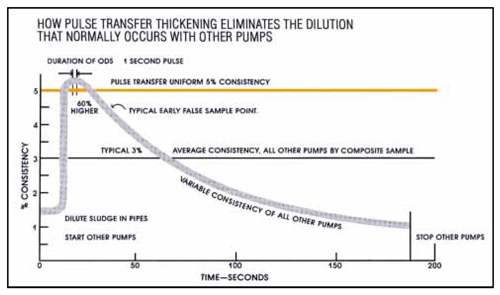

Because the sludge accumulation rate in the clarifier is so low, it is standard practice to use some kind of timed cycle withdrawal where the pumps operate at high rate for several minutes at a time, somewhere between 50 and 200 gallons per minute. Now, here's what generally happens in traditional timed cycle pumping systems. When sludge is withdrawn, the first sludge to reach the pump at the beginning of each new pumping cycle is the dilute sludge that remained in the suction line at the end of the previous pumping cycle. This is followed immediately by a high consistency sludge from the bottom maximum compression region of the sludge blanket. And here's where the problems begin. Particles that are compressed have a tendency to stay put and impede hydraulic flow. Particles that are more loosely agglomerated have less resistance to hydraulic flow. The pump tends to attract less compact sludge through regions of lesser hydraulic resistance and the net result is more and more dilution as the pumping cycle continues. This becomes a serious and extensive problem. The chart shown below graphically depicts what happens in a typical time cycled pumping system. Comparing theory and the real world provides some interesting insights. Many treatment plants will boast sludge consistency rates in the 5 to 6% solids range and have records to prove it. Yet they may be only averaging 3% consistencies at best (as the chart indicates). This is because operators tend to draw a sample at the beginning of a cycle, where it might be 5 to 6%, rather than at the end of the cycle, where the consistency might only be half that. So if conventional pumping systems withdraw sludge at high consistency at the beginning of the pumping cycle, and at very low consistency at the end of the cycle, with the degree of consistency diminishing as the cycle continues from beginning to end, it would seem that the only way to assure drawing off sludge of constant high consistency would be to shut the pump off after a second or so of operation, start it again, stop it again, and so forth; very impractical from the standpoint of operator attention and wear and tear on the pump.

Why Pulse Transfer Thickening Solves the Dilution Problem

The Pulse Transfer Thickening Capability of the ODS® pump enables it to remove sludge continuously from the settling tank, pumping sludge from the bottom of the sludge blanket at the rate at which it accumulates there. In other words, the pumping rate is automatically matched to the sludge accumulation rate. Required velocities are maintained automatically. What Pulse Transfer Thickening really means is that the plant can draw thickened sludge continuously without any loss of the turbulent scouring velocity to keep solids in suspension and without risk of clogging the pipes. Pulse Transfer Thickening works efficiently no matter how low the sludge accumulation rate. Based on the experiences encountered by treatment plants utilizing Pulse Transfer Thickening, we find an average increase in sludge consistency of about 60%. This is because rather than drawing off hundreds of gallons of sludge in a timed cycle, as in conventional pumping systems, with the ODS® pump only 4.5 gallons of sludge is withdrawn with each pulse.

How the ODS® Pump Produces Pulse Transfer Thickening

The ODS® is a diaphragm pump equipped with an exclusive spring-assist mechanism. Air is applied at the top of the diaphragm, forcing the diaphragm down, compressing the spring. The amount of air pressure is adjustable and determines the degree of velocity, completely independent of the sludge flow rate. Peak scouring velocity occurs near the end of each pulse. Pumping rate is adjusted by controlling the dwell period between pulses. The ODS® spring assist produces a comparable peak suction pulse following each discharge stroke, refilling the pump chamber with sludge. The air required for the ODS® in variable rate primary sludge service is only about 0.4 hp per mgd of influent. It may seem incredible that a modestly-priced diaphragm pump can deliver economic benefits several times the pump's original cost per year, but our experience to date proves exactly that.

Some of the Benefits Pulse Transfer Thickening Yields

Processing diluted sludge can be very expensive, and particularly wasteful in energy. By utilizing Pulse Transfer Thickening, a treatment plant can realize the following significant benefits:

- Typically 60% increase in primary and similar sludge consistencies.

- Typically three times greater consistencies in activated sludge wasted from a quiescent hopper in three-product final clarifier.

- Uniformly high consistency sludge.

- Uniformly stable sludge blanket.

- Consistent loads on drive heads and rakes.

- Prevention of denitrification processes.

- Serve as a viable alternative to separate thickeners, especially for primary sludge.

Pulse Transfer Saves Money in Other Ways

There are many ways Pulse Transfer Thickening can impact favorably on treatment plant operations. For one thing, with a 60% increase in sludge consistency you can obtain a 40% reduction in the volume of sludge being handled throughout the plant. Taking the anaerobic digester as an example, here is how this produces significant savings in operating costs:

- There is 40% less sludge so you need 40% less digester capacity.

- You need 40% less heat to bring the sludge up to mesophilic operating temperature.

In existing digester installations, higher consistency sludge will increase detention time. This will result in increased methane production. Also, higher consistency sludge reduces the volume of volatile solids, saving in dewatering and disposal cost. Besides the economics, consider some of the other important benefits that can be realized in digester operation from Pulse Transfer Thickening. Many of the causes of costly digester upsets can be eliminated because:

- Continuous versus batch sludge transfer provides better control.

- There is continuous or frequent incremental feeding of the bacteria.

- There is a stable alkaline buffer for the acid and methane formers.

- Higher alkalinity results because protein concentration in the sludge is increased.

- The 40% reduction in wash-out of solids and organisms maintains the methane producers in the tank.

- Maintaining a uniform digester temperature eliminates thermal shock to bacteria.

- There is a 40% reduction in supernatant to be treated.

- By increasing the consistency of the sludge to the digester, the end result is a stable sludge more suitable for land disposal or for soil conditioning.

For more information on this product and to view the in-depth statistics please click here to read the full PDF brochure.